350 Chevrolet Distributor

Understanding the 350 Chevrolet Distributor: A Comprehensive Guide

The 350 Chevrolet distributor is a crucial component in the ignition system of your classic Chevy, responsible for distributing the high-voltage spark to the right cylinder at the perfect moment. A well-functioning distributor ensures your engine runs smoothly and efficiently. In this blog post, we’ll delve into the intricacies of the 350 Chevrolet distributor, covering its parts, operation, and maintenance, so you can keep your Chevy purring like a kitten.

The Anatomy of a 350 Chevrolet Distributor

To truly appreciate the importance of the distributor, let’s first break down its key components:

Distributor Cap: This plastic or composite cover houses the spark plug wires and protects the internal components from dirt and moisture.

Rotor: The rotor is a small, conductive component that rotates inside the distributor cap, directing the high-voltage spark to the correct spark plug wire.

Contact Block: Also known as the “points,” this component controls the flow of electricity to the coil, triggering the spark.

Condenser: The condenser is a small capacitor that smooths the electrical current, preventing damage to the points.

Distributor Shaft: The shaft is the rotating axis of the distributor, driven by the camshaft. It carries the rotor and controls the timing of the spark.

Advance Mechanism: This mechanism adjusts the timing of the spark, ensuring it occurs at the optimal moment for maximum power and efficiency.

Vacuum Advance: Some distributors feature a vacuum advance, which uses engine vacuum to further adjust the timing, improving performance and fuel efficiency.

Ignition Coil: The ignition coil transforms the low-voltage current from the battery into the high-voltage spark required for combustion.

Spark Plug Wires: These insulated wires carry the high-voltage spark from the distributor to the spark plugs, igniting the air-fuel mixture in the cylinders.

How the 350 Chevrolet Distributor Works

The distributor operates in a precise sequence, ensuring each cylinder receives a spark at the right time:

Camshaft Rotation: As the camshaft rotates, it drives the distributor shaft, causing the rotor to spin inside the distributor cap.

Points Open: At a specific point in the rotation, the points open, allowing current to flow from the battery to the coil.

Coil Activation: The coil transforms the low-voltage current into a high-voltage spark, which is directed to the rotor.

Rotor Rotation: The spinning rotor directs the high-voltage spark to the correct spark plug wire, which carries it to the corresponding cylinder.

Spark Plug Ignition: The spark plug ignites the air-fuel mixture in the cylinder, initiating the combustion process.

Points Close: As the distributor shaft continues to rotate, the points close, cutting off the current to the coil and resetting the cycle.

Maintaining Your 350 Chevrolet Distributor

To ensure your distributor operates smoothly and efficiently, regular maintenance is key:

Cleanliness: Keep the distributor cap and rotor clean and free of dirt and oil. Use a soft brush and a mild cleaner to avoid damaging the components.

Point Adjustment: Check and adjust the points regularly. Worn or improperly gapped points can cause misfires and poor performance.

Condenser Check: Inspect the condenser for signs of damage or wear. A faulty condenser can lead to points arcing and premature failure.

Vacuum Advance: If your distributor has a vacuum advance, ensure the vacuum hose is connected and free of leaks. A malfunctioning vacuum advance can result in poor performance and fuel economy.

Ignition Coil: Inspect the ignition coil for cracks or leaks. A faulty coil can cause misfires and reduced spark intensity.

Spark Plug Wires: Inspect the spark plug wires for cracks, fraying, or corrosion. Replace them if necessary to maintain a strong spark.

Cap and Rotor: Replace the distributor cap and rotor every few years, or sooner if you notice signs of wear or arcing.

Upgrading Your Distributor

If you’re looking to enhance the performance of your 350 Chevrolet, consider upgrading your distributor:

Performance Distributors: Performance distributors offer improved advance curves and higher-quality components, resulting in better ignition timing and increased power.

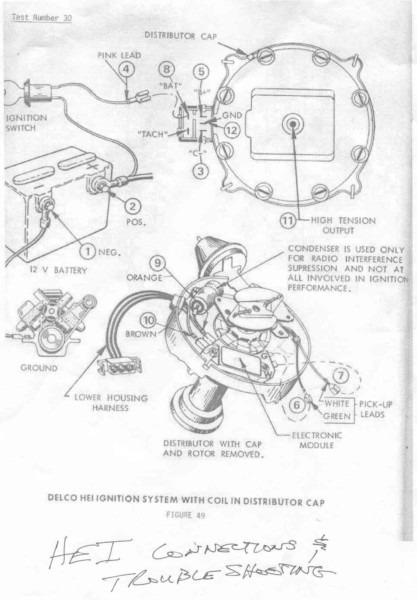

Electronic Ignition: Upgrade to an electronic ignition system, which eliminates the need for points and condensers. Electronic ignition provides more precise timing and improved spark intensity.

Distributor Hold-Down Clamp: Ensure your distributor is securely mounted with a quality hold-down clamp. A loose distributor can lead to timing issues and poor performance.

Troubleshooting Common Distributor Issues

No component is immune to problems, and distributors are no exception. Here are some common issues and their potential solutions:

Misfires: If you’re experiencing misfires, check the spark plug wires, distributor cap, and rotor for damage or wear. Replace any faulty components.

Poor Performance: Inspect the points for wear and adjust the gap if necessary. A faulty condenser or vacuum advance can also cause poor performance.

No Spark: Check the ignition coil for cracks or leaks. Ensure the spark plug wires are securely connected to the distributor and spark plugs.

Timing Issues: If your engine is running rough or lacks power, check the distributor shaft for wear or damage. A worn shaft can affect timing accuracy.

Advanced Timing: If your engine is running too hot or experiencing detonation, the distributor advance mechanism may be advancing the timing too much. Adjust the advance curve or consider an aftermarket performance distributor.

Conclusion

The 350 Chevrolet distributor is a vital component in your classic Chevy’s ignition system, ensuring each cylinder receives a spark at the right moment. By understanding its anatomy, operation, and maintenance, you can keep your distributor in top shape and your engine running smoothly. Whether you’re a weekend warrior or a professional mechanic, the knowledge gained from this guide will empower you to tackle distributor-related issues with confidence.

FAQ

Can I upgrade my distributor to an electronic ignition system?

+Absolutely! Upgrading to an electronic ignition system eliminates the need for points and condensers, providing more precise timing and improved spark intensity. It’s a great way to enhance the performance and reliability of your 350 Chevrolet.

How often should I replace the distributor cap and rotor?

+As a general rule, it’s recommended to replace the distributor cap and rotor every 3-5 years or sooner if you notice signs of wear or arcing. Regular replacement ensures optimal performance and reduces the risk of misfires.

What are the signs of a faulty ignition coil?

+A faulty ignition coil can manifest as misfires, poor engine performance, or a lack of power. Inspect the coil for cracks, leaks, or damage. If you suspect a faulty coil, it’s best to replace it to avoid further issues.

How do I adjust the distributor advance curve?

+Adjusting the distributor advance curve requires specialized tools and knowledge. It’s recommended to consult a professional mechanic or refer to a trusted repair manual for detailed instructions specific to your 350 Chevrolet model.

Can I use a distributor from a different Chevy model on my 350 Chevrolet?

+It’s not recommended to use a distributor from a different Chevy model without proper research and compatibility checks. Distributors from different models may have different advance curves, timing specifications, or physical dimensions, which can lead to timing issues and poor performance.