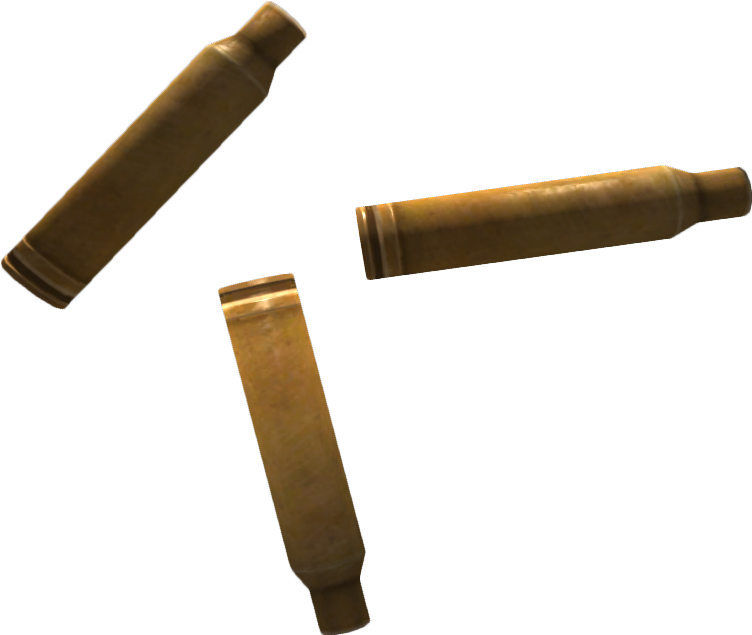

Ultimate 5 Tips To Design Your Rifle Bullet Casing

Crafting your rifle bullet casing is an art, a delicate dance between precision engineering and creative design. This guide will unveil the secrets to crafting a bullet casing that not only performs admirably but also stands out aesthetically. Let's dive into the world of bullet casing design and explore the steps to create a masterpiece.

1. Understand the Fundamentals of Bullet Casing Design

Before embarking on your design journey, it's crucial to grasp the basics of bullet casing. Bullet casings, also known as cartridges, are the heart of your ammunition. They hold the propellant and the bullet, providing the necessary structure for the firing process. Understanding the different components of a bullet casing, such as the primer, powder, and bullet, is essential for creating a functional design.

Additionally, familiarize yourself with the various types of bullet casings available, such as rimfire and centerfire casings. Each type has its own unique characteristics and is suited for specific applications. Rimfire casings, for instance, are commonly used in small-caliber rifles and pistols, while centerfire casings are more versatile and can be found in a wide range of firearms.

2. Define Your Design Objectives

Every bullet casing design should start with a clear set of objectives. Consider the intended use of your ammunition. Are you designing for target shooting, hunting, or self-defense? Each application requires different considerations. For example, target shooting may prioritize accuracy and consistency, while hunting might focus on stopping power and terminal ballistics.

Additionally, think about the aesthetic appeal of your design. Do you want a classic, traditional look, or are you aiming for a more modern, innovative style? The design of your bullet casing can reflect your personal taste and add a unique touch to your ammunition.

3. Choose the Right Materials

The choice of materials is a critical aspect of bullet casing design. Different materials offer varying levels of strength, durability, and compatibility with different types of ammunition. Common materials used in bullet casing construction include brass, steel, and aluminum. Each material has its own advantages and disadvantages, so choose wisely based on your specific requirements.

Brass, for instance, is a popular choice due to its excellent corrosion resistance and ability to withstand high pressures. It is commonly used in centerfire casings and provides a good balance between strength and ease of manufacturing. Steel, on the other hand, is known for its durability and is often used in rimfire casings. Aluminum, although less common, offers lightweight and corrosion-resistant properties, making it suitable for specialized applications.

4. Optimize the Internal Dimensions

The internal dimensions of your bullet casing play a crucial role in its performance. These dimensions include the primer pocket, powder capacity, and bullet seating depth. Optimizing these dimensions ensures that your ammunition functions reliably and consistently. Here are some key considerations:

- Primer Pocket: Ensure that the primer pocket is large enough to accommodate the primer and provide adequate space for ignition. A properly sized primer pocket helps prevent hang-fires and ensures consistent ignition.

- Powder Capacity: Consider the amount of propellant your bullet casing can hold. This directly affects the velocity and power of your ammunition. Choose a powder capacity that aligns with your intended use and the desired performance characteristics.

- Bullet Seating Depth: The depth at which the bullet is seated in the casing affects its stability and accuracy. A properly seated bullet ensures consistent flight characteristics and helps minimize variations in velocity.

5. Add Aesthetic Touches

Once you have the functional aspects of your bullet casing design covered, it's time to add some aesthetic flair. Customizing the appearance of your bullet casing can make your ammunition truly unique. Here are some ideas to enhance the visual appeal:

- Engraving: Add intricate engravings or etchings to your bullet casing. This can include patterns, logos, or even personalized messages. Engraving not only adds a touch of elegance but also provides a durable mark that will withstand the test of time.

- Color Options: Experiment with different colors and finishes. Brass casings, for example, can be anodized or plated to achieve a variety of colors, ranging from subtle hues to vibrant shades. This adds a pop of color to your ammunition and makes it stand out.

- Custom Headstamps: Create custom headstamps, which are the markings on the base of the bullet casing. These can include your own logo, initials, or a unique design. Custom headstamps not only add a personal touch but also serve as a mark of authenticity and quality.

Remember, when adding aesthetic touches, ensure that they do not compromise the functionality or safety of your bullet casing. Always prioritize performance and reliability over purely decorative elements.

Conclusion

Designing your rifle bullet casing is a meticulous process that requires a deep understanding of ammunition fundamentals, clear design objectives, and careful material selection. By optimizing the internal dimensions and adding unique aesthetic touches, you can create a bullet casing that not only performs exceptionally but also reflects your personal style. So, whether you're a competitive shooter, a hunter, or simply a firearms enthusiast, crafting your own bullet casings can be a rewarding and satisfying endeavor.

How do I ensure the safety of my custom bullet casings?

+

Safety should always be a top priority when designing bullet casings. Ensure that your casings meet industry standards and regulations. Regularly inspect your casings for any signs of damage or wear and replace them if necessary. Always follow proper handling and storage guidelines to maintain the integrity of your ammunition.

Can I use recycled materials for bullet casing design?

+

While recycling is an environmentally conscious practice, it’s important to note that not all materials are suitable for bullet casing construction. Some recycled materials may not meet the necessary strength and durability requirements. It’s best to consult with experts or refer to industry guidelines to determine the suitability of recycled materials for your specific application.

How can I improve the accuracy of my ammunition?

+

Accuracy in ammunition is influenced by various factors, including bullet weight, powder charge, and barrel length. To improve accuracy, consider using high-quality components and fine-tuning your bullet casing design. Experiment with different bullet weights and powder charges to find the optimal combination for your specific firearm and intended use.

Are there any legal considerations when designing bullet casings?

+

Yes, it’s important to be aware of the legal aspects of bullet casing design. Different countries and regions have varying regulations regarding ammunition manufacturing and ownership. Ensure that you are familiar with the laws and regulations in your area and obtain any necessary licenses or permits before engaging in bullet casing design and production.

Can I design bullet casings for different calibers?

+

Absolutely! Bullet casing design can be tailored to different calibers, allowing you to create ammunition for a wide range of firearms. Each caliber has its own specific requirements, so it’s important to research and understand the dimensions and characteristics of the caliber you wish to design for. This ensures that your bullet casings will be compatible and perform optimally with the intended firearm.